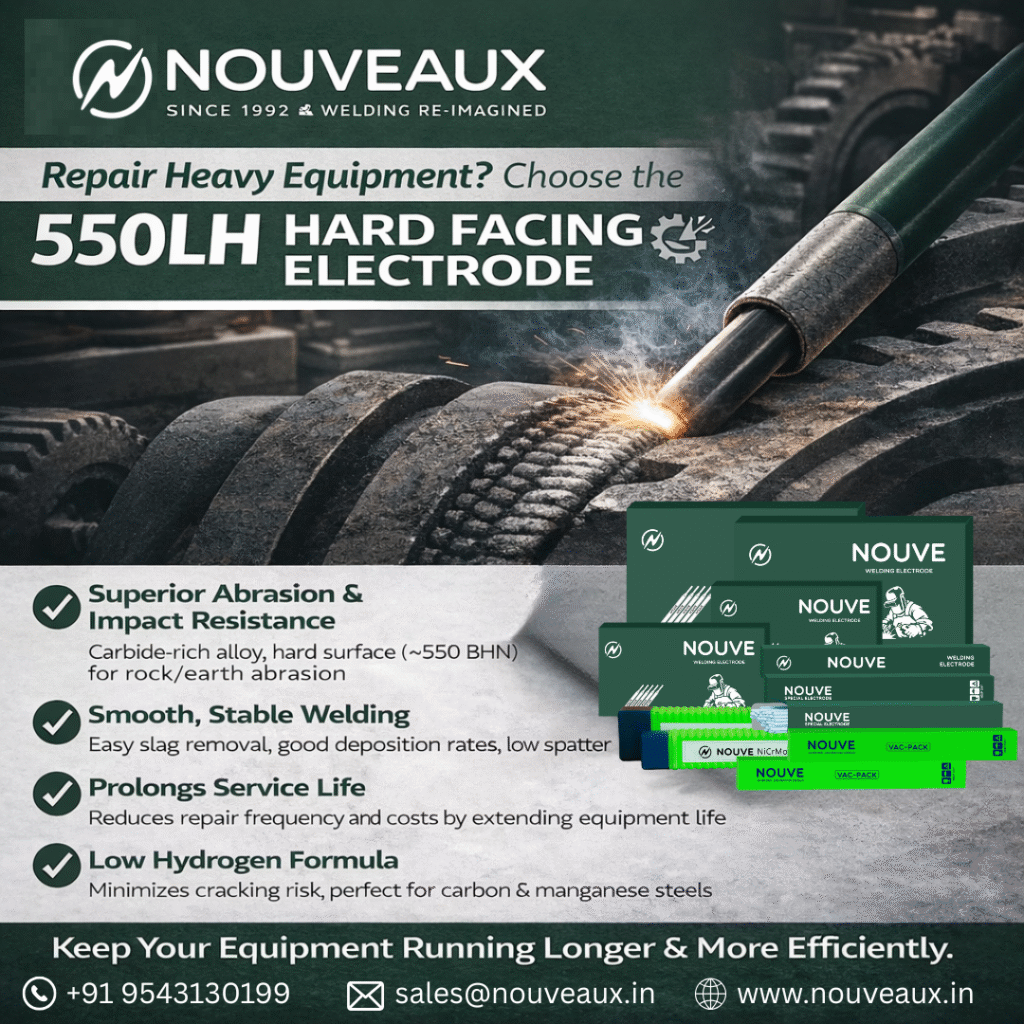

In the demanding world of industrial maintenance and repair, downtime is the enemy, and equipment longevity is king. When critical machinery components wear down—from crusher hammers and mill liners to shafts and gears—the choice of repair material isn’t just a detail; it’s a strategic decision. Enter the 550LH Hard Facing Electrode, a specialized tool that has become a go-to solution for maintenance teams worldwide. Here’s why it deserves a prime spot in your repair arsenal.

1. Exceptional Abrasion and Impact Resistance

The core strength of the 550LH lies in its unique alloy composition. It deposits a high-chromium, carbide-rich weld metal that creates an extremely hard, wear-resistant surface (typically reaching 550 Brinell hardness or more). This isn’t just about surface hardness; it’s designed to withstand both severe abrasion (the grinding, scraping wear from minerals, gravel, or soil) and moderate to heavy impact—the kind that shatters lesser materials. This dual capability makes it incredibly versatile for a wide range of punishing applications.

2. Designed for Smooth, Stable Welding

The “LH” in its name often stands for “Low Hydrogen” and “Hardness,” but for the welder, it translates to “easier to use.” Compared to many hard-facing electrodes, the 550LH is known for:

- Smooth Arc Characteristics: It provides a stable, controllable arc with minimal spatter.

- Easy Slag Removal: The slag forms a cohesive layer that peels off easily, speeding up the process and improving efficiency.

- Good Deposition Rates: You can build up worn areas effectively, saving time and material.

This user-friendly nature reduces operator fatigue, minimizes rework, and ensures consistent, high-quality overlays even in less-than-ideal repair conditions.

3. Outstanding Versatility Across Industries

The 550LH electrode is a true workhorse across multiple sectors:

- Mining & Quarrying: Ideal for rebuilding crusher rolls, mantles, hammers, and bucket teeth.

- Construction: Protects loader blades, grader edges, excavator buckets, and crusher components.

- Agriculture: Extends the life of tillage tools, plowshares, and chopper blades.

- Steel & Cement Plants: Perfect for rebuildling fan blades, pulverizer hammers, and conveyor screws exposed to abrasive materials.

- General Heavy Equipment Repair: For any carbon or manganese steel component subjected to wear.

4. Cost-Effectiveness Through Extended Lifecycles

The ultimate goal of any industrial repair is to make equipment last longer than it did originally. By applying the 550LH electrode, you’re not just patching a component—you’re engineering a more resilient surface. This dramatically extends service intervals, reduces the frequency of repairs, and delays the massive capital expense of full component replacement. The return on investment is clear: lower cost per operating hour and maximized uptime.

5. Reduced Risk of Cracking

Low-hydrogen electrodes are critical for welding on high-strength or thick-section steels. The 550LH’s low-hydrogen coating minimizes the risk of hydrogen-induced cracking (HIC) in the weld metal and heat-affected zone (HAZ). This is crucial for maintaining the structural integrity of the repaired part, especially when dealing with high-stress components or in environments where failure is not an option.

6. Flexibility in Application

It is commonly used for both build-up (restoring dimension to a worn part) and overlay (applying a final wear-resistant layer). With the correct technique, it can be applied in multiple layers to achieve the desired thickness and protection. This flexibility makes it a single solution for many stages of the repair process.

When Should You Specifically Choose the 550LH?

Consider the 550LH Hard Facing Electrode when your repair checklist includes:

- Components suffering from severe metal-to-rock/earth abrasion.

- Parts that also endure moderate to heavy impact.

- A need for a balance between superior wear resistance and weldability.

- Repairs on carbon or manganese steels.

- Situations where minimizing downtime is critical.

Best Practice Tip:

For optimal results, always ensure the base metal is clean (free of rust, oil, and moisture), follow the manufacturer’s recommended amperage and preheat/interpass temperature guidelines, and use the appropriate welding technique (often a stringer or weave bead as specified).

The Bottom Line

In the relentless environment of industrial operations, the 550LH Hard Facing Welding Electrode stands out as a reliable, high-performance solution. It successfully bridges the gap between extreme durability and practical weldability. By choosing it, you’re not just making a repair—you’re making a strategic investment in the longevity, reliability, and cost-efficiency of your most valuable assets.