In the demanding world of industrial welding, where structural integrity and project longevity are non-negotiable, the choice of consumables makes all the difference. For submerged arc welding (SAW) applications requiring EL8 grade wire, selecting the right manufacturer isn’t just a procurement decision—it’s a commitment to quality, reliability, and performance.

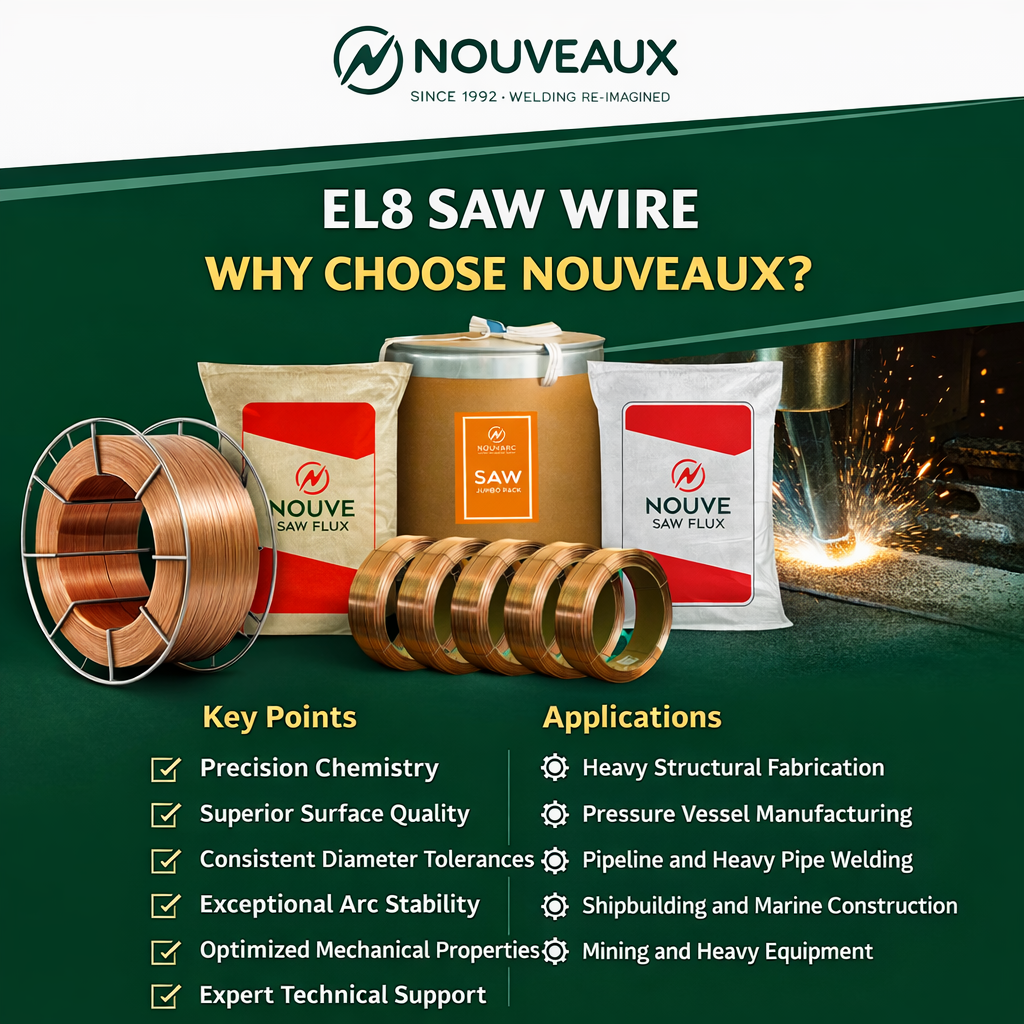

At Nouveaux, we don’t just produce welding wire; we engineer solutions. Here’s why industry leaders consistently choose Nouveaux for their EL8 SAW wire needs.

Uncompromising Material Science

EL8 submerged arc wire is specifically designed for welding medium-carbon, high-strength steels. Its composition ensures optimal strength and crack resistance in critical applications. At Nouveaux, our metallurgical expertise transforms this specification into a consistent, superior product:

- Precision Chemistry: We maintain tighter elemental controls than industry standards require, ensuring every batch delivers predictable, excellent weld metal properties.

- Superior Surface Quality: Our proprietary drawing and cleaning processes result in exceptionally clean wire surfaces, minimizing the risk of inclusions and porosity for cleaner, stronger welds.

- Consistent Diameter: Tolerances are held to exacting standards, ensuring smooth, uninterrupted feedability in automated and semi-automated SAW systems.

Performance That Speaks Volumes

What does our quality translate to on your shop floor or job site?

- Exceptional Arc Stability: Produces smooth, even beads with excellent sidewall fusion, reducing rework and improving deposition efficiency.

- Optimized Mechanical Properties: Delivers weld metal with the right balance of tensile strength, impact toughness, and ductility as required by EL8 specifications.

- Low Spatter & Easy Slag Removal: Maximizes operator efficiency and minimizes post-weld cleanup time.

The Nouveaux Difference: Beyond the Wire

Choosing a manufacturer is about partnership, not just product. Here’s what sets the Nouveaux experience apart:

1. Technical Partnership & Support

Our team doesn’t disappear after the sale. We provide comprehensive welding procedure support, troubleshooting assistance, and optimization recommendations to help you achieve the best possible results with our wire.

2. Rigorous Quality Assurance

Every coil of Nouveaux EL8 SAW wire is backed by a multi-stage QA process. From raw material inspection to final packaging, we document and verify quality at each step, providing full traceability and certified mill test reports for critical projects.

3. Reliability & Supply Chain Integrity

We understand that downtime is costly. Our strategic inventory management and efficient logistics ensure you get the right wire, in the right quantity, exactly when you need it.

4. Commitment to Innovation

We continuously refine our processes and products. By investing in R&D, we ensure our EL8 wire not only meets today’s standards but anticipates tomorrow’s challenges in fabrication, shipbuilding, pressure vessel construction, and heavy structural work.

Engineered for Your Application

Nouveaux EL8 SAW wire is the trusted choice for demanding applications across industries:

- Heavy Structural Fabrication (bridges, buildings, offshore platforms)

- Pressure Vessel and Boiler Manufacturing

- Pipeline and Heavy Pipe Welding

- Shipbuilding and Marine Construction

- Mining and Heavy Equipment Manufacturing

Make the Strategic Choice

In welding, the cheapest consumable often becomes the most expensive choice when you factor in rework, downtime, and compromised integrity. Quality welding wire is an investment in your project’s success, your team’s productivity, and your company’s reputation.

Choose Nouveaux EL8 SAW wire—where scientific precision, consistent quality, and unwavering support converge to give you not just a product, but a performance advantage.