In the world of fabrication, not all weld joints are created equal. Some are routine, while others are critical—the ones that hold the entire system’s integrity, safety, and performance in your hands. Think pressure vessels in a chemical plant, deep-sea pipeline components, or high-temperature processing equipment. For these applications, the choice of filler metal isn’t just a detail; it’s a decision that defines the project’s success and longevity.

When joining high-performance nickel alloys like Hastelloy C-276, C-22, and C-2000, one filler metal stands out as the gold standard: T-NiCrMo-3. Often known by its AWS A5.14 classification and synonymous with the ERNiCrMo-3 wire, this filler is the unsung hero for the most demanding environments.

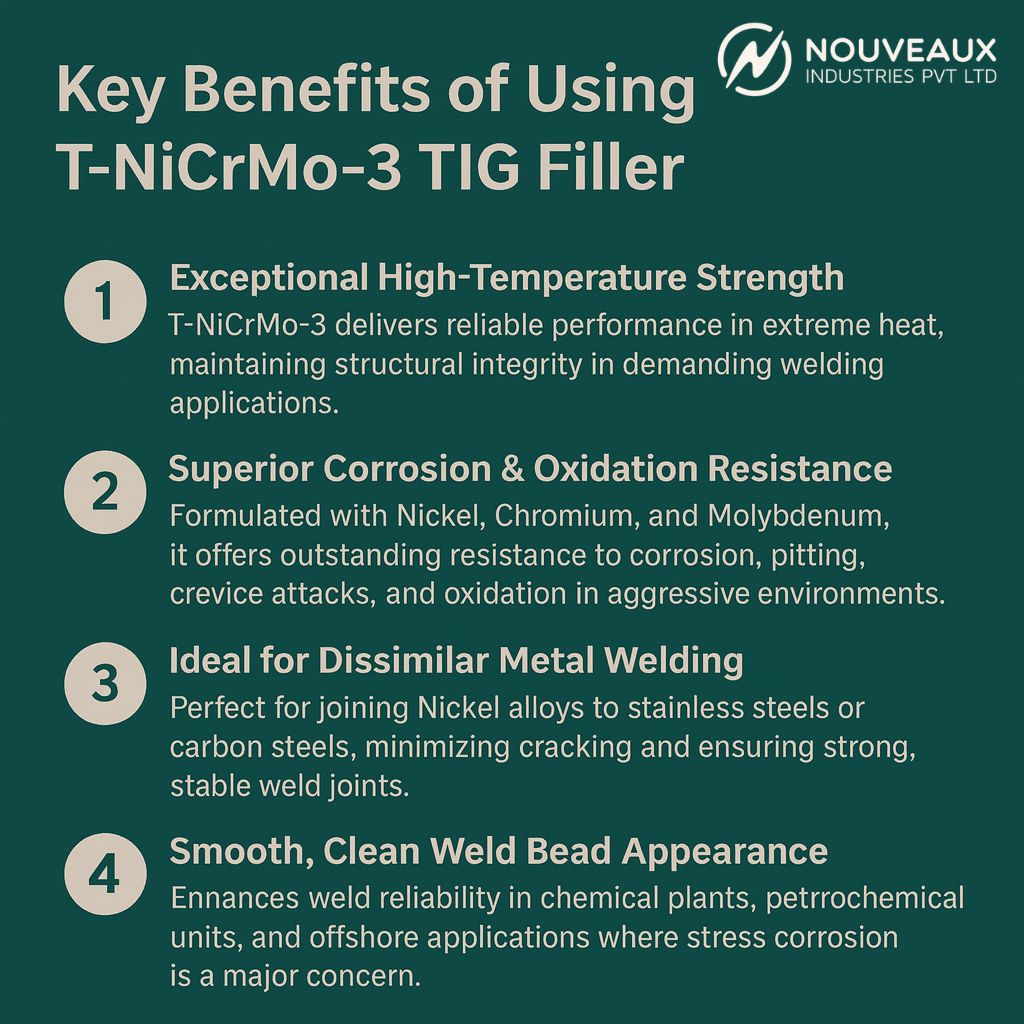

Let’s break down the key benefits that make T-NiCrMo-3 the go-to choice for your most critical weld joints.

1. Unmatched Corrosion Resistance: The Primary Defense

This is the single biggest reason to specify T-NiCrMo-3. It’s designed to withstand a veritable “who’s who” of industrial corrosives.

- Pitting & Crevice Corrosion: With a high Molybdenum (Mo) content (typically 9%), it resists chloride-induced pitting and crevice corrosion, a common failure point in seawater, chemical processing, and pulp & bleach plants.

- Oxidizing and Reducing Environments: The balanced chemistry of Chromium (Cr) and Molybdenum allows it to perform brilliantly in both oxidizing acids (like nitric acid) and reducing acids (like sulfuric and hydrochloric acid).

- Stress Corrosion Cracking (SCC): It offers exceptional resistance to chloride-induced stress corrosion cracking, a major concern in refineries and offshore applications.

Bottom Line: If your component faces harsh chemicals, saltwater, or polluted environments, T-NiCrMo-3 provides a weld deposit that is as corrosion-resistant as the parent materials it’s joining.

2. Excellent High-Temperature Performance

While not primarily a “super-alloy” for jet engines, T-NiCrMo-3 maintains excellent strength and oxidation resistance at elevated temperatures. This makes it ideal for applications like:

- Flue gas desulfurization systems (scrubbers)

- Heat exchangers

- Pyroprocessing equipment

Its ability to resist the formation of harmful secondary phases during prolonged heat exposure ensures long-term stability and prevents premature failure.

3. Superior Weldability and Operator-Friendly Characteristics

From a welder’s perspective, T-NiCrMo-3 is a dream to work with, especially using the precise TIG (GTAW) process.

- Good Arc Stability: The weld puddle is fluid and controllable, allowing for smooth, consistent bead profiles.

- Low Wetting Angle: This promotes excellent fusion to the joint sides, reducing the risk of lack-of-fusion defects—a critical factor in code-quality work.

- Forgiving Nature: It is more tolerant of minor surface imperfections and oxide films than some other high-nickel alloys, though proper cleaning remains essential.

These characteristics result in higher-quality welds with fewer defects, reducing the need for costly and time-consuming repairs.

4. Versatility Across a Family of Alloys

One of the most practical benefits of T-NiCrMo-3 is its versatility. It is the recommended filler metal not just for one, but for a whole family of nickel-chromium-molybdenum alloys, including:

- Hastelloy C-276 (UNS N10276)

- Hastelloy C-22 (UNS N06022)

- Hastelloy C-2000 (UNS N06200)

- Alloy 59 (UNS N06059)

This simplifies procurement and reduces the risk of using the wrong filler on the shop floor. It’s also excellent for welding these alloys to dissimilar metals, such as stainless steel or other nickel alloys.

5. Consistent, Coded Quality for Critical Applications

Filler metals like T-NiCrMo-3 are manufactured to stringent standards like AWS A5.14. This means every spool or rod delivers a consistent chemical composition and mechanical properties. For projects requiring ASME, API, or NADCAP certification, using a coded and traceable filler metal is not an option—it’s a requirement. T-NiCrMo-3 provides the documented pedigree needed for these critical applications.

When Should You Specify T-NiCrMo-3?

Consider T-NiCrMo-3 your first-choice candidate for TIG welding when your project involves:

- Chemical Processing Equipment: Reactors, vessels, and piping handling harsh acids and chlorides.

- Pollution Control & Scrubbers: Components exposed to corrosive flue gases and acidic condensates.

- Marine & Offshore Applications: Seawater-cooled heat exchangers, piping systems, and subsea components.

- Pharmaceutical and F&B: Where ultra-pure, corrosion-resistant surfaces are mandatory.

- Any joint where failure is not an option.

Conclusion: Don’t Compromise on the Critical Link

The weld is often the weakest link in a fabricated component. By choosing T-NiCrMo-3 TIG filler for your critical nickel alloy joints, you transform that potential weakness into one of the strongest parts of your system. It’s an investment in corrosion resistance, structural integrity, and long-term operational reliability.